Peer review model lead time: 4 weeks

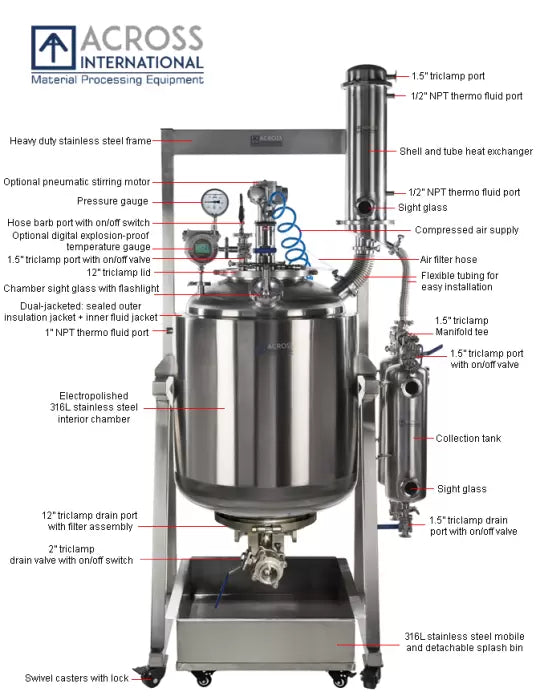

Ai 316L Grade Stainless Steel Reactor Features

- Built-in lift for safe and easy filter removal

- Detachable 12" 316L stainless steel filter assembly for easy cleaning

- Dual jacketed. Sealed outer insulation jacket provides best temperature performance inside chamber

- All wetted parts on main vessel and lid built with pharmaceutical grade 316L SST

- Shell and tube heat exchanger with 70 tubes for the best condensing results

- ElectroPolished internal chamber

- Greatly reduces surface roughness by leveling micro-peaks and valleys

- Improved vacuum pressures, out-gassing rates, and pumping speed

- Prolong equipment lifespan by reducing friction and wear

- Much better sterilized and semiconductor grade surface

- Essential for the food and pharmaceutical industries

- Detachable condenser and collection tanks

- Dual collection tanks with big sight glass allows you to drain without breaking vacuum

- High drain port clearance for easy draining or added filtration

- Large ports (top 12” bottom 12”) allows for easy chamber cleaning

- Top placed vacuum port on condenser provides better flow and condensing results

- No messy cable, with space saving integrated stirring motor controller

- Heavy-duty stainless-steel frame with swivel casters

- Built-in flashlight gives you a clear view inside the chamber

- Tons of tri clamps adapters available, e.g. tri clamp to hose barb/KF25/NPT

- Flexible bellow condenser connection reduces shipping damage

- Electric motor and controller model is ETL certified to UL and CSA standards

- Peer reviewed model (pneumatic motor and controller) is approved to be used with Acetone, Ethanol, Heptane, Hexane, Isopropyl Alcohol, Methanol, and Pentane.

CAUTION!

- Never fill circulated heaters or chillers with water, always use Ai or manufacturer's recommended thermal fluid

- Always leave ample fluid space in heater reservoir to allow fluid heat expansion

Shell and Tube Heat Exchanger

Standard Quick-Change 316L Stainless Steel Propeller Agitator

SPECIFICATIONS

|

Standard package

|

SPECIFICATIONS

|

Standard package

|

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.