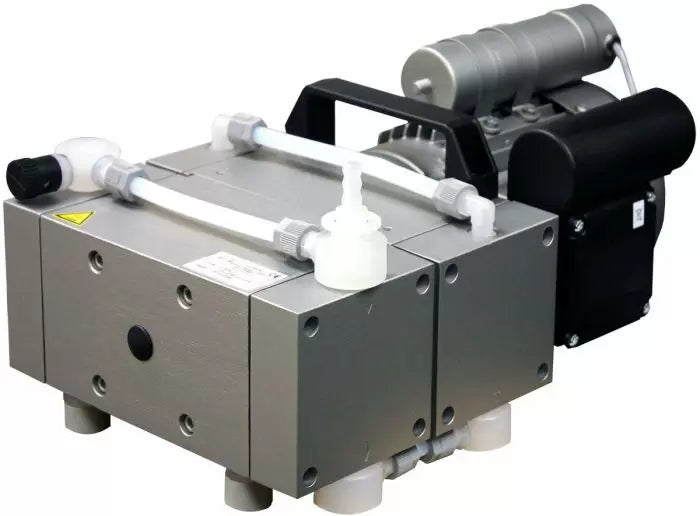

The diaphragm pump consists of a pump casing and a drive motor.

The pump casing contains the drive unit and four pump heads. Each pump head contains a diaphragm and the work valves.

Two pairs of pump heads are arranged opposite each other.

The pump heads are driven via an eccentric shaft with a connecting rod.

1 to 4 stage pumps are supplied, depending upon the circuitry of the pump heads.

Welch Chemical Duty vacuum pumps use dry, oil-free membrane (diaphragm) technology to deliver faster pumping dynamics that support filtration, evaporation, drying, degassing, impregnation, and other rough vacuum applications.

There are twelve models available, with free air displacement from 0.8 cfm to 7.8 cfm, and ultimate vacuum pressure as deep as 1.5 torr. All have strong pumping dynamics to near their ultimate vacuum pressure.

DryFast family models are CSA certified; 4-head and 8-head models are cUL listed. All have 1PH motors with built in thermal protection.

Welch Chemical Duty dry vacuum pumps can be used for vacuum degassing, vacuum impregnation, rotary evaporators, vacuum ovens, vacuum filtering, solid phase extraction, falling film evaporators, rough vacuum distillations, gas recycling, leak detection, gas sampling and many other laboratory and industrial applications. 1.5/2.0 torr models can strip DMF @ 35C or be used with vacuum ovens.

|

Specification

|

|

Standard Package

|

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.