DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well ventilated areas. DO NOT USE INDOORS

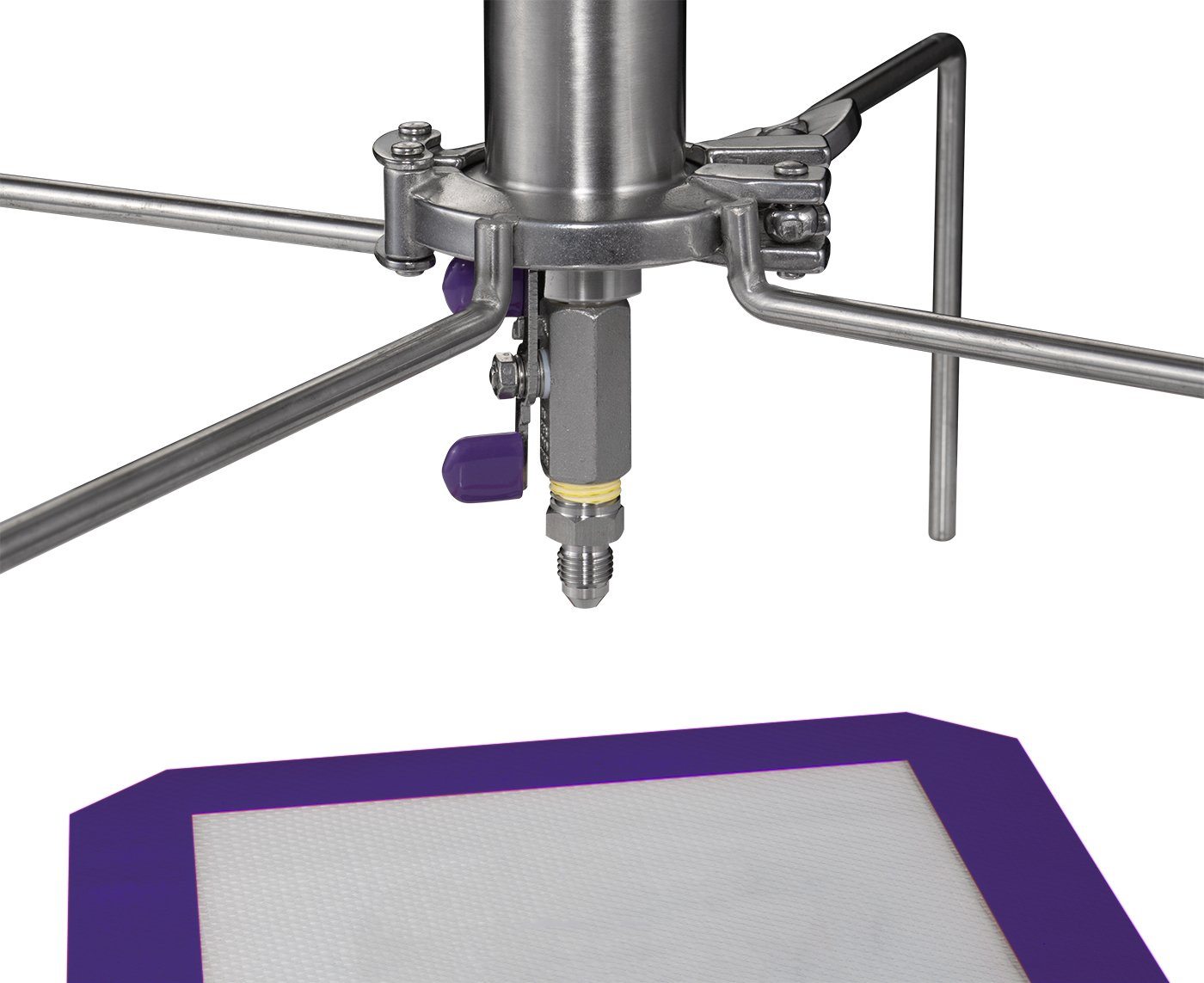

Our dewaxing closed column extractor is the primary tool for extracting maximum solvent, and is designed to increase productivity. This closed system can be filled about 85% with solvent before the internal pressure will equal the pressure of the can propellant.

Adding dry ice to the dewaxing column on the outside of the extractor decreases the temperature of the extractor, which filters out coagulated waxes and lipids from being extracted. This provides a more efficient and productive extraction process.

With a 2” stainless steel tube, this unit can be customized to your needs, handling everything from 90-270g of material. Pressure gauge, shower head, and sight glass can all be added to increase ease of use.

Key Features and Description:

- Closed Column Pressure Extractor (Comes with 1 yr. Limited warranty, excludes gaskets and screens)

- Compound Gauge with (-30)-160 PSI readout.

- This system allows the user to build up solvent pressure by closing the valve, pulling a vacuum and filling the extractor, Extractor will fill about 85% with solvent before the internal pressure will equal the pressure of the can propellant.

- The solvent can will fit into either port with a tip adapter supplied with some butane cans, tip adapter required, not included

- Solvent Soak is expected to be between 30-90 min, but this all depends on material, starting with frozen cans of solvent is recommended

- This system allows the user to soak the material before opening the bottom valve to release the solvent and oil.

Professional Kit Adds the following:

- Compound Gauge

- Sight Glass

- Shower Head

Explorer Kit Includes the Following:

- Spool Sizes Specifications:

- 2" x 12" = 115G

- 2" x 18" = 150G

- 2" x 24" = 200G

*Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%.

For best results, we recommend to tightly pack coarse ground material.

***Note: Parts and components can be subject to substitutions. Any substituted parts will have the same function and will be of equal or greater value.****

Cylinder Volume

Select Material

How Much Will Fit in Cylinder

Formula

Volume x Weight of Water x Specific Gravity

Constants

Weight of Water = 0.0360 (lbs / in3)

Specific Gravity of =

Account for an 80% fill to avoid a hydraulic lock

How Much Material Will Fit in the Cylinder

| Packing Density (g) | 2.5 | 3 | 3.5 | 4.3 |

| Grams of Material | ||||

| Lbs. of Material |

Cans of Butane by Size

| mL | fl oz | lbs | # of Cans |

|---|---|---|---|

| 420 | 14.2 | ||

| 300 | 10.1 | ||

| 200 | 6.7 | ||

| 150 | 5.07 |

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.