***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.***

***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors

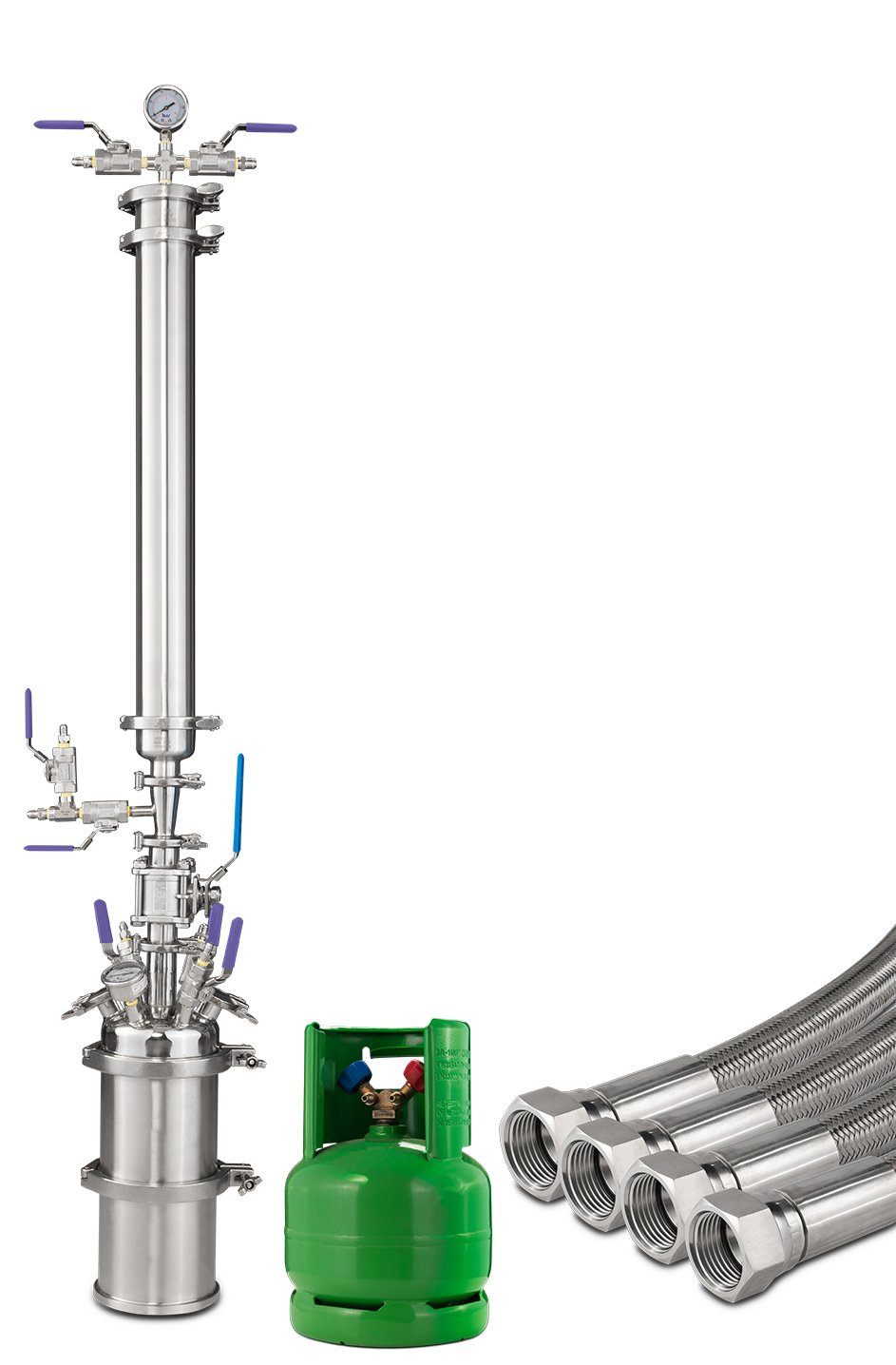

1LB MK-V Orthrus Bidirectional Flow Closed Loop Extractor

(System comes with 1 yr. limited warranty)

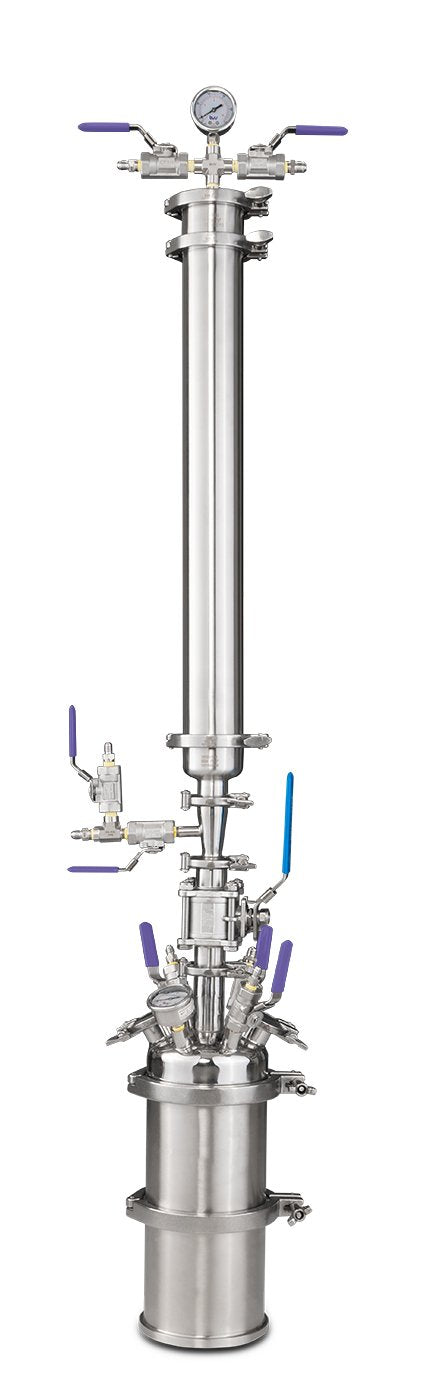

The 1lb Bi-Directional closed loop increases efficiency by utilizing both a bottom and top solvent input. By using a bottom flood on the first wash, you ensure all material has seen solvent. This method preventing channeling through the material. Finish the run with a top flood input to ensure all residuals have been washed from the material. Oil bearing solvent is collected in the collection base under the material column. Once collected, solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent.

Extractor Configurations:

- Explorer: Our standard bi-directional extractor model. Comes with a welded bottom base and standard LP tank. This model provides all the benefits of the Orthrus design without any bells and whistles. The Explorer model is perfect for those looking to get the bi-directional performance but have a budget. Explorer models can be upgraded after purchase.

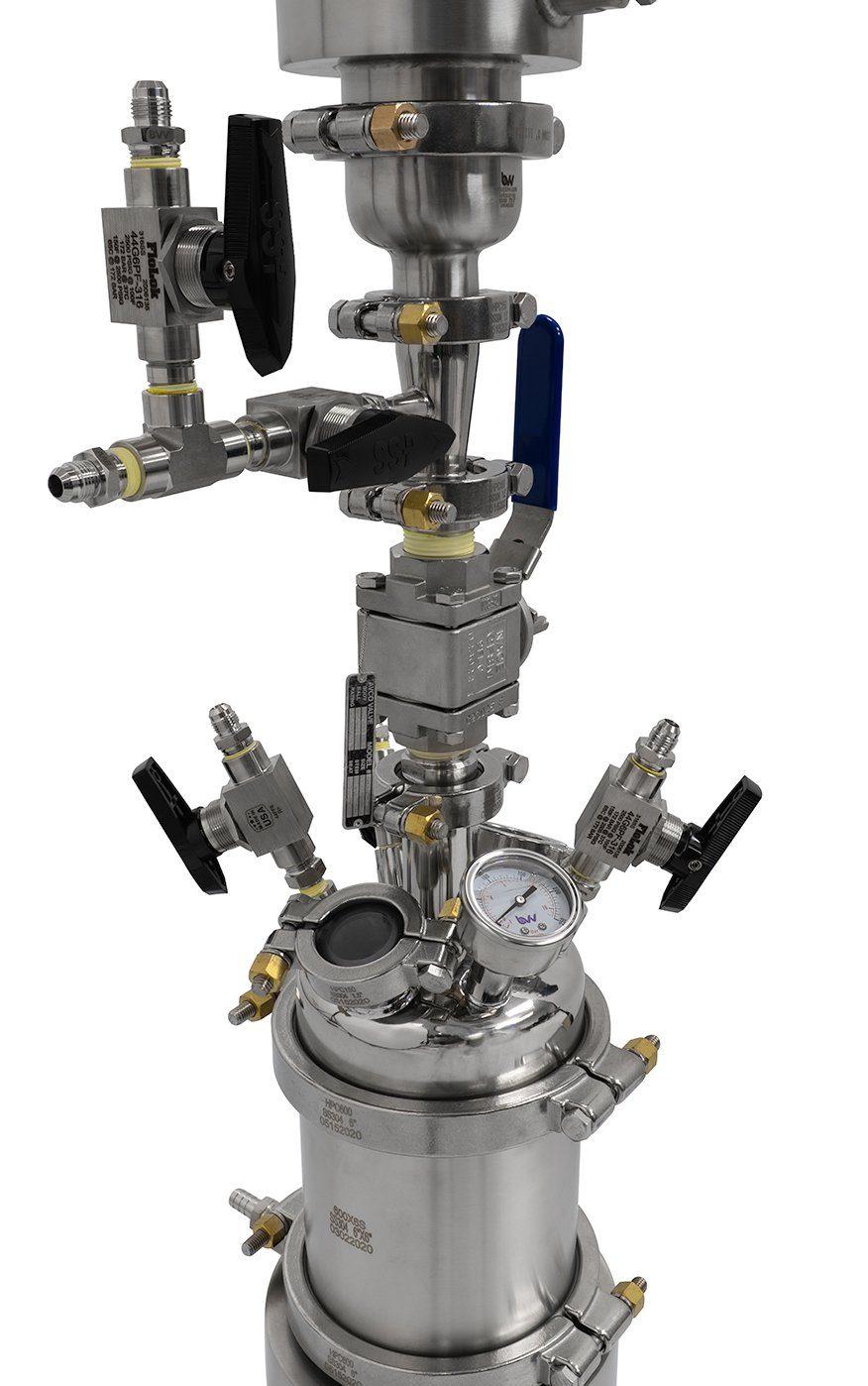

- Professional: This model features upgrades to help produce a higher quality extract. Solvent is entered into the system through an injection coil. This coil is chilled with dry ice and alcohol, dropping solvent temperatures to dewax inline. Fats and waxes are not soluble when solvent temperature is subzero, so chilling solvent on input is the simplest way to achieve high clarity extract. The Professional also comes with a removable bottom on the collection base. This makes removal of extract after the run as easy as possible. High pressure clamps give greater solvent compatibility, allowing propane to be used.

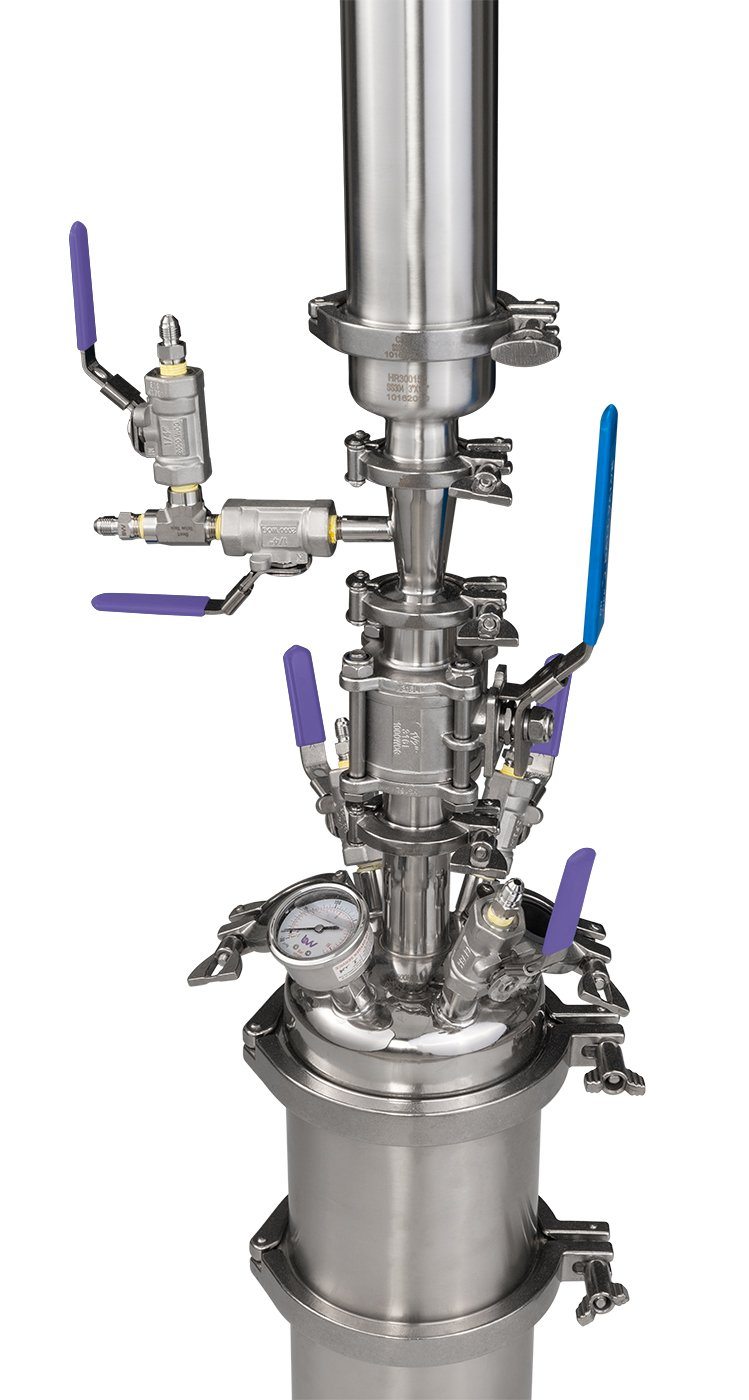

- Elite: The Elite series is our fully upgraded Orthrus model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. The elite series comes with all American instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve and jacketed collection base. Full dewaxing is guaranteed by combining both an injection coil and sleeved column. Both units are packed with dry ice, making both solvent and material sub-zero temperatures. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. *NOTE* This model requires a heater circulator or chiller

| Explorer | Professional | Elite |

|---|---|---|

|

|

|

Unit Includes:

- Collection Base

- 6"x6" Welded Bottom Base

- 6"x6" Open Spool

- Assembled 6" bi-flow lid

- 3"x24" Material column with reducer & top cap

- 3" filter plate kit

- 1.5" Solvent input manifold

- 1.5" Ball Valve

- Mastercool 6LB Solvent Recovery Tank

- (2) 1/4" 48" High Pressure PTFE Braided SS Hose

- 3/8" 48" High Pressure PTFE Braided SS Hose

- (2)6" clamps, (3)3" clamps and a (3)1.5" clamp with gaskets

- (2)3" Gaskets w/ filter

- Instruction Manual

Specifications:

- 3"x 24" 304 Stainless Steel Material Tube 1lb (450g)

- 316 Stainless Steel Fully Encapsulated Miniature Ball Valves

- System Rated to 150PSI

- Multiple port connections for _" 316 Stainless JIC 37 Degree

- 304 Stainless Steel Base Container 6" diameter by 12" tall

- Tri-Clamps at all interfaces make for a high pressure, easy clean unit.

- Viton Gaskets are designed for Oil Processing Temp range -40-200F

- Dimensions (Inches): 25" x 7" Diameter overall size

- Weight: 21 lbs.

- Operating Temperature Range: -40F to 160F

- Ultimate Vacuum: as low as 10 Microns

- Base unit Maximum Capacity: 300 cubic inches, (2.553 Liters)

- Construction: All components made of 304 Stainless Steel.

- Max Vacuum -29.9inHg

- High Polish Interior

*Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%.

For best results, we recommend to tightly pack coarse ground material.

Cylinder Volume

Select Material

How Much Will Fit in Cylinder

Formula

Volume x Weight of Water x Specific Gravity

Constants

Weight of Water = 0.0360 (lbs / in3)

Specific Gravity of =

How Much Material Will Fit in the Cylinder

| Packing Density (g) | 2.5 | 3 | 3.5 | 4.3 |

| Grams of Material | ||||

| Lbs. of Material |

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.