VACUUM PUMP MOBILE CART ONLY AVAILABLE IF YOU PURCHASE A PUMP AND A DIGITAL VACUUM CONTROLLER.

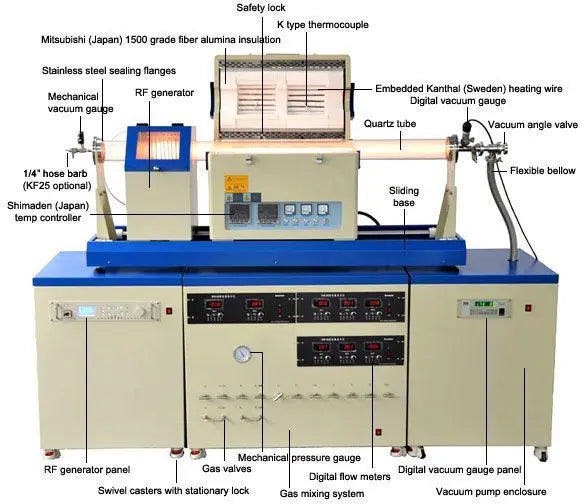

STF1200 series Chemical Vapor Deposition (CVD) and Plasma-Enhanced Chemical Vapor Deposition (PECVD) single or multi-zone split tube furnaces feature the famous Kanthal (Sweden) wire heating elements embedded in high quality Mitsubishi (Japan) alumina fiber insulation. All steel dual-layer housing ensures durability and helps minimize heat loss to exterior surface.

Furnace operation is controlled by Eurotherm (UK) digital controller with built-in digital communication, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results.

Controller Option:

3504 can do 50 segments programmer (ramp and dwelling)

Features

- Compact and portable design.

- Lower processing temperatures required compare to conventional CVDs.

- Film stress can be controlled by high/low frequency mixing techniques.

- Top-open furnace chamber for fast and easy tube access.

- Standard package includes set of stainless steel vacuum sealing flanges with valves and pressure meter.

- Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

- Multiple atmosphere processes in a single cycle are possible (ex: binder burn out in air and parts sintering under rough vacuum or inert gas environment.)

- Built-in amp meter and dual voltmeters for easy monitoring and troubleshooting.

- Built-in computer interface.

- Long life type K thermocouple.

- Furnace rail option gives you ultra fast cooling rates

Safety

- Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller's manual) or when the thermocouple is broken or malfunctions.

- Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

Warning! NEVER fill furnace with explosive gases, including Hydrogen, Carbon Monoxide and Methane.

| Tube material | Quartz |

| Heating element | Kanthal® (Sweden) A1 2.0 resistance coil wire |

| Max. vs constant working temperatures | 1200°C max. and 1100°C constant |

| Thermo couple type | K |

| Refractory lining | Mitsubishi® (Japan) 1500 grade fiber alumina |

| Temperature controller | Eurotherm® (UK) |

| Maximum heating rate | < 30°C / min |

| Temperature controller precision |

+/- 1°C (+/- 1.8°F) |

| Vacuum sealing flange kit |

Stainless steel vacuum sealing flanges with one vacuum gauge, |

| Electrical requirements | 208-240VAC, 50/60 Hz, single phase |

RF generator specifications

| Electrical requirements | 208-240 volts 50/60 Hz |

| Output power | 5 to 500 watts, adjustable in +/-1% step |

| RF frequency |

13 MHz with +/-0.005% stability |

| Reflection power |

200 watts max. |

| Matching | Automatic |

| RF output port |

50 Ω, N-type, female |

| Cooling | Air |

|

Part description |

Quantity |

Part image |

| STF1200 split tube furnace | 1 set | |

| Multi-channel gas supply system | 1 set | |

| Plasma RF power supply (optional) | 1 set | |

| Vacuum pump and enclosure (optional) | 1 set | |

| Quartz tube | 1 pc | |

| Stainless steel vacuum sealing flanges w/ pressure meter | 1 set |

|

| Stainless steel hook | 1 pc |

|

| Thermal block | 1 set |

|

| Thermal gloves | 1 pair |

|

| Spare fuse | 2 pcs |

|

| USB/RS485 computer interface kit | 1 set |

|

| Furnace and Shimaden controller manual | 2 pcs |

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.